Monitoring and Protection Systems for highest safety requirements

Our major OEM-customers have occasion to meet highly specific requirements about the protection of rotating equipment and turbomachinery such as turbines, compressors, and expanders. Protection against overspeed as well as other trip criteria must be guaranteed.

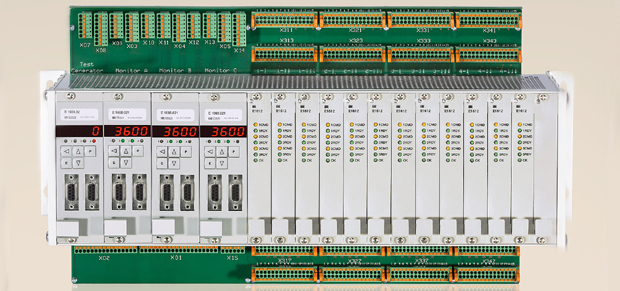

Triple Channel Protection Systems TMR (triple-modular-redundant), OEM solutions in 2oo3 architecture

♦ Additional functions to the TMR standard versions according to project requirements as:

♦ Shutdown of downstream 2oo3 valve control circuits

♦ Triple channel redundancy also for add-ons

♦ Additional 2oo3-Load-Enable-Modules for E/H-Converter

♦ Additional digital inputs for digital trip criteria

♦ Additional analog inputs for analog trip criteria

♦ Last Blade Protection

♦ Individual valve control

♦ Counters for number of starts and hours of operation

View Details

♦ Maintenance-free during Lifetime, therefore minimized TCO

♦ Highest safety at maximum availability due to true 2oo3 architecture for each trip criterion within each Monitor

♦ Extremely low PFD value (Probability of Failure on Demand), less than 1% of allowable value for a SIL3 loop

♦ Replacement of all active components during operation possible (hot swap and highest availability)

♦ TMR (triple-modular-redundant) system with sensor monitoring and self-test

♦ Highest safety levels with maximum availability by unique and true 2oo3 architecture for each trip criterion within each Monitor

♦ Maintenance-free during lifetime due to integrated automatic proof tests

♦ Automated tests of the valve control outputs with permanent monitoring of the feedback by the Test Generator

♦ Minimal Total Cost of Ownership

♦ Requires less than 1% of the permissible PFD value for a SIL3 Safety Loop

♦ Enhanced safety values due to an integrated Test Generator

♦ Replacement of all active components during operation (Hot Swap)

♦ TUV certified for safety level SIL3 / IEC 61508:2010

♦ TUV certified for PL e; Cat. 3 / DIN EN ISO 13849-1:2008

♦ TUV certified for SILCL3 / IEC 62061:2005

♦ API670 and API612 compliant

♦ 2 PROFIBUS Interfaces

♦ Additional features for E16A358 SIEMENS:

- Individual 2oo3 valve control (expandable up to 96 valves)

- Status feedback of the valve controls to the PLC/DCS via PROFIBUS